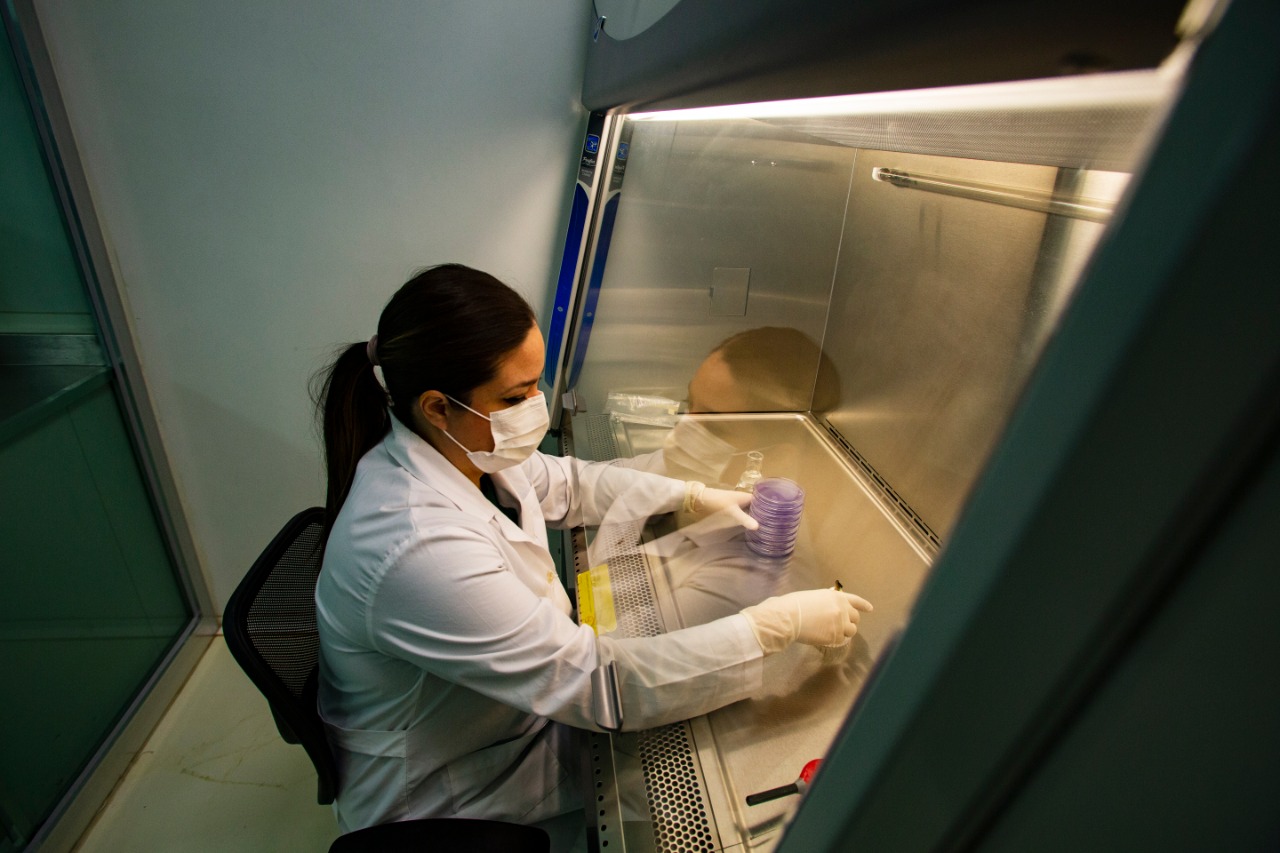

Super Starr met together with TIPA, United Fresh, FDA, ProExport, & Senasica to establish the Texas International Produce Association’s Best Practices Manual. In 2012 when the FDA was forced to stop papayas from shipping from Mexico, Super Starr’s papayas were the first to be put on the green-list as we participated in meetings with top officials from FDA to reassure them of our commitment to providing the U.S. consumer safe, healthy, and sustainable papaya. We’ve continued to be fortunate to be a leader in food safety for papayas through these best practices:

Identify & produce solutions to fungus, bacterias and virus problems found on the farms, which has helped to reduce chemical usage by almost 70%.

Test and Evaluate use of organic & conventional fertilizers to improve efficiency in usage.

Test internally for E. Coli & Salmonella on the farm and in packing facilities.